Hydraulic cylinders have been of great help. They have made heavy-duty lifting, bending, and other tasks very straightforward. However, these cylinders come in various types, each offering a unique value proposition. The debate around single acting vs double acting hydraulic cylinders confuses buyers.

Single-acting cylinders are suitable for simple tasks. Their cost-effectiveness and easy maintenance make them stand out. But double-acting cylinders are extremely popular. 75% of the revenue of the cylinder market comes from double-acting cylinder types. This stat indicates their demand.

However, single- and double-acting cylinders are very different. Before making a final decision, it is necessary to understand their differences. Why? Because they’ll help you know which cylinder is suitable for what! So, keep reading, and I will go into the details. You’ll get a head-to-head comparison of these cylinders.

Overview of Single & Double Acting Hydraulic Cylinders

Single Acting Acting Hydraulic Cylinders

Double Acting Hydraulic Cylinders

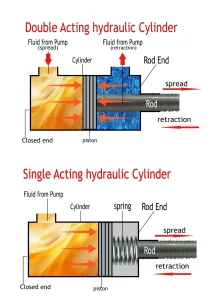

Their main difference is in the direction of fluid driving the piston. The single-acting cylinder uses a fluid in one direction. The fluid can either push or take the piston back to its position. The double-acting cylinders use fluid on both sides of the piston. So, the piston both moves and is brought back with hydraulic fluid.

The single-acting cylinders are unidirectional. They use fluid on one side of the piston, which presses it. The piston returns to position through external force such as gravity or spring. The second-acting cylinders are bidirectional in terms of putting pressure. They use fluid on both sides of the pistons. The piston presses and retracts through this fluid instead of external force.

When pressed in a confined area, fluid transits in all directions equally. This is a statement of Pascal’s law; these cylinders work on this rule. They both use fluid, which applies pressure on the piston. The piston then moves and completes the required task. The single-acting cylinders are straightforward in their work.

They don’t have complex designs or components. This is both good and bad. Simplicity makes them easy to maintain but lowers their functionality as well. On the other hand, the double-acting hydraulic cylinders are very advanced. They consist of complex components that enhance their functionality. Keep in mind that these hydraulic cylinders are not new.

They were first invented back in the 1700s. Joseph Bramah was the first to use these cylinders in press machines in 1795. They are extensively used now in different machines. For one-way pressing, manufacturers use single-acting cylinders. For two-way functionality, the double cylinders come in handy.

What are the Differences between Single & Double Acting Hydraulic Cylinders?

The above-given answer is just a short overview. Remember, these cylinders have many differences that make them fit for various applications. I can’t mention all of their distinctions in a paragraph. I will compare these two cylinders head to head in the section below. You’ll learn their differences and decide which cylinder works best for what.

1- Retraction Methods

Retraction means the return of the piston from its initial position. As you know, these hydraulic cylinders use fluid to push the piston. However, how this piston comes back varies in both of these cylinders. The single cylinders use fluid on the side of the piston. This fluid pushes it, and then there is no fluid to retract the piston.

An external force is used to retract the piston. Generally, single-acting cylinders come with heavy-duty springs. These springs retract the piston back to its initial position. On the other hand, double-acting cylinders don’t use such springs. They use fluid on both sides of the piston, which plays a role in retraction.

Once the piston is pressed, the opposite fluid fills the chambers. As a result, the hydraulic fluid exerts pressure on the piston. Due to this pressure, the piston returns to its original or initial position. This makes double-acting cylinders very efficient in the long run. They don’t need external force for retraction.

2- Connection Ports

The hydraulic cylinders consist of connection ports. Don’t know what these ports are? These are holes or inlets that allow fluid to enter and exit the chamber. In the single-acting cylinder, there is one connection port. As I said earlier, these cylinders use fluid on one side of the piston. That’s why only a single connection port is enough for fluid to enter and exit the chamber.

On the flip side, double-acting cylinders have two connection ports. This is because they use fluid in two directions. One port is on the upper part of the cylinder, and the other is on the lower side. Fluids enter from the upper port and apply pressure to the piston. As a result, the piston moves down and does its job.

During retraction, fluid enters the chamber from the lower connection. This fluid again applies pressure to the piston, causing it to move back to its initial position. The fluid present in the upper chambers exits through the upper connection port. This is how the two connected ports operate in the double-acting cylinders.

3- Design Complexity

The single-acting hydraulic cylinders are very simple in their construction. They consist of fewer components and parts. This simplicity is both good and bad. Due to their simplicity, their maintenance is easy. You don’t have to be an expert to operate or maintain these machines. That’s the good part – but this simplicity also limits their functionality.

These single-acting cylinders are not suitable for heavy-duty tasks. On the other hand, double-acting cylinders have more complex constructions. They consist of multiple components that work together to complete the specific task. Malfunctioning in any single part would cause these cylinders to fail.

However, these double cylinders work very intensely. They can be used in heavy-duty machines. Have you seen those excavators and forklifts? These heavy-duty machines use double-acting hydraulic cylinders for their functionality. However, their regular maintenance is costly. You’ll need expert mechanics for their regular checks.

4- Performance & Efficiency

The double-acting hydraulic cylinders are superior in performance. Why? Because they use the bi-directional movement of the piston through the fluid. So their operation is quicker. You won’t see any downtime. Moreover, they can do complex tasks with their extreme power. The return of the piston to its initial position would be smooth.

On the flip side, the single-acting cylinders working are not smooth. You’ll have to use an external force to retract the piston. Generally, a spring is used to put the piston back. But this spring can be prone to breaking or malfunctioning. This results in downtime of these hydraulic cylinders. That’s why I consider the double-acting cylinder more efficient.

5- Applications & Usability

Both single-acting and double-acting cylinders are helpful and are used in different machines. Single-act hydraulic cylinders are suitable for mild applications but cannot handle heavy-duty tasks. Conversely, double-acting cylinders are powerful. So, they are used in big machinery to ensure better performance.

From automotive to construction, these cylinders find their application in various sectors. Here is a comparison of their applications:

| Single-Acting Cylinder Applications | Double-Acting Cylinder Applications |

| Car jacks for simple lifting tasks. | Vehicle suspension systems, car lifts. |

| Dump trucks for loading and unloading. | Excavators, bulldozers, cranes, and loaders. |

| Mining truck bed lifts. | Ship steering systems and cargo winches. |

| Used in clamping devices. | Aircraft landing gear, flaps, and brake systems. |

| Hydraulic Door Closers. | Robotic arms, conveyor systems, Forklifts. |

6- Cost & Affordability

The double-acting hydraulic cylinders are very expensive. They fall into the premium category. On the flip side, single-acting cylinders are less costly. However, their working and functionality are also limited. Many people are attracted to single-acting cylinders due to their affordable pricing. But I don’t support buying these unless you only need a cylinder for simple tasks.

Remember, double-acting cylinders offer heavy-duty functionality. Their high prices are genuinely worth the investment. These cylinders are very versatile and can be used in various machines. Their exceptional power enables them to complete any task with ease. Conversely, single-acting cylinders are limited and only suitable for basic functionality.

Pros & Cons of Single & Double Acting Hydraulic Cylinders

In the section above, I mentioned all of their differences. You might be at a point where you consider both cylinders equally good. That’s true, but they are still suitable for different applications. Still confused about which to choose for your work? Worry not! Let’s discuss the pros and cons of these two-cylinder types. They will further help you make wise selections.

| Advantages of Single-Acting Cylinders | Advantages of Double-Acting Cylinders |

| A simple design with fewer moving parts | Provides force in both directions |

| Cheaper to manufacture and purchase | Offer more versatility and better performance |

| Uses less hydraulic fluids | Handles heavier loads and more complex tasks |

| Smaller size, ideal for tight spaces | Doesn’t rely on external forces for retraction |

| Less maintenance due to simplicity | Offer 100% uptime as don’t need external force |

These are the advantages of these two cylinders. This table may show you a single side of the picture. But I want you to know both the good and bad sides. Only then you’ll be able to make wise decisions. Knowing only goods can mislead you towards wrong decision-making. Here is the table showing their limitations:

| Cons of Single-Acting Cylinders | Cons Double-Acting Cylinders |

| Limited as use fluid on one side of piston | Complex construction with more components |

| Slower retraction is due to reliance on external forces such as springs. | These cylinders and their maintenance are very costly. |

| Not suitable for tasks needing bidirectional force | Uses more hydraulic fluid as both sides of pistons consist of these fluid |

| Very weak and less suitable for heavy-duty machines | The size of these cylinders is bulky which takes more space during use. |

Remember, both of these cylinders come with pros and cons. In simple words, none of them is perfect. You should make your decision and consider the features you need. Remember, there is no one size fits all. Analyze your needs and use them before making a final decision. However, people prioritize double-acting cylinders due to their versatile performance.

Frequently Asked Questions

What are the advantages of a double-acting hydraulic cylinder?

These cylinders offer excellent performance. They use fluid on both sides of the pistons to apply pressure. This makes them suitable for heavy-duty machinery. Moreover, they are very efficient, as they don’t need any external force (spring) for their work.

What is the difference between single-action and double-action cylinders?

Single-acting cylinders use unidirectional pressure on the piston. So, they use a dedicated spring to retract the piston back to its position. They are simple and only suitable for mild work. Double-acting cylinders are very complex and use bidirectional pressure. Fluid both pushes and retracts the piston back without needing any additional spring. These cylinders are more efficient in terms of performance.

What is the principle of a single-acting cylinder?

Single-acting cylinders work on Pascal’s law. They use fluid and expert pressure on the piston. Per Pascal’s law, the pressure applied to fluid divides evenly in the confined area. As a result of this pressure, the piston moves down and gets the job done.

Which should I choose, single or double-acting cylinders?

There is no single-line answer. Their selection depends on your needs and purpose. However, I recommend using double-acting cylinders. They are more powerful and can be used in heavy-duty machines. You’ll get all your simple to complex tasks done efficiently.

Conclusion

The purpose of this article is not to declare one as the winner. Instead, I tried to explain their differences. Keep in mind that both of these hydraulic cylinders are excellent in their ways. The single-acting cylinders are an affordable option with limited functionality. On the other hand, the double-acting cylinders are costly.

However, their high pricing comes with versatility and exceptional performance. They use bidirectional pressure on the piston, which makes these cylinders fast. You should carefully analyze each of their distinctions and make wise decisions. Remember, one small mistake can buy you the wrong cylinders that may not fit your needs.