Product Features and Advantages:

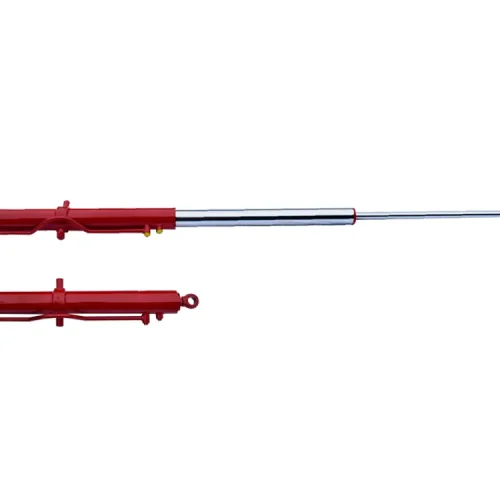

The piston rod guide ring, made from phenolic fabric, performs well from -35℃ to 110℃, offering excellent wear resistance, low friction, minimal deformation, and superior shock absorption..

Automatic welding welding joint niform firm and beautiful

The front end cover in the updated design integrates a guide bushing, and both the front and rear end covers are made of carbon steel plates with blackening treatment for rust prevention. The steel plate dimensions can be flexibly selected to suit various operating conditions, with a short processing cycle.

The plunger wiper reduces contamination and extends the cylinder’s lifespan

The piston uses an O-ring for the inner diameter and a polyurethane Y-ring for the outer diameter, preventing leakage and withstanding high pressure.

The surface has a smooth black baked enamel finish for corrosion resistance and enhanced appearance. Its compact, lightweight design maximizes stroke in confined spaces..

The piston sealing mechanism utilizes two polyurethane Y-rings for reliable sealing performance, low friction resistance for smooth operation, and excellent pressure resistance, making it suitable for a wide range of pressure applications. With a simple structure, moderate cost, and easy installation, it is highly practical. The polyacetal guide ring provides high mechanical strength, good oil resistance, low water absorption, and high wear resistance, allowing it to endure significant lateral and reverse stresses.

Scope of application

Tractor rear suspension hydraulic cylinder

Hydraulic cylinder for electric mobile medium lift shear lift

Hand pushed hydraulic platform lift

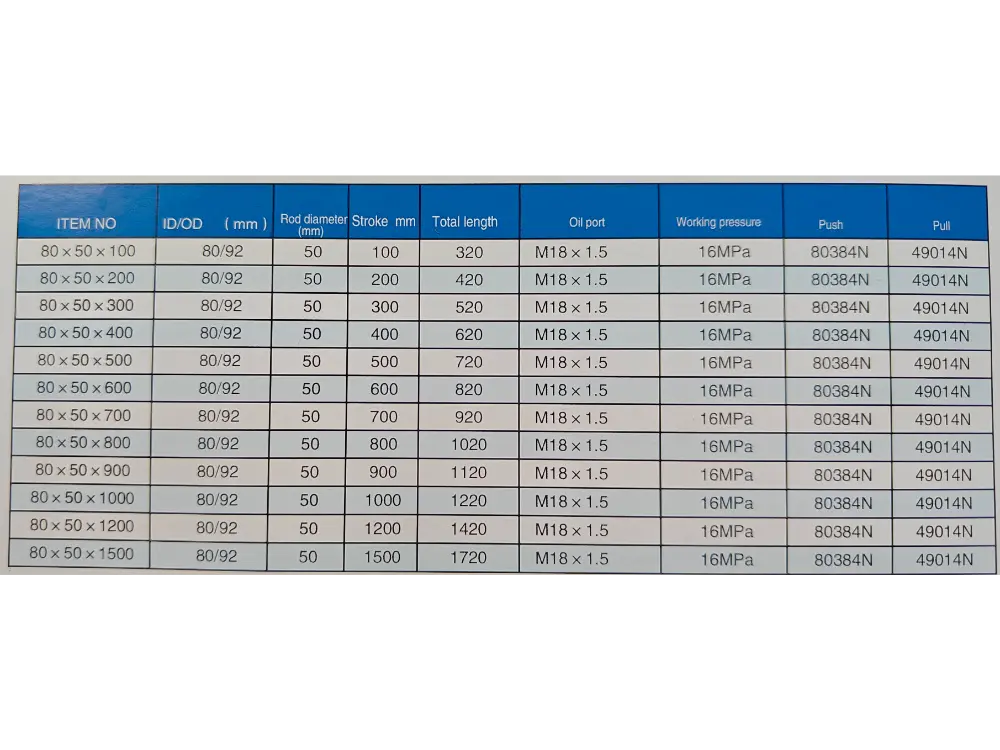

Technical parameters:

| Parameter | Specification |

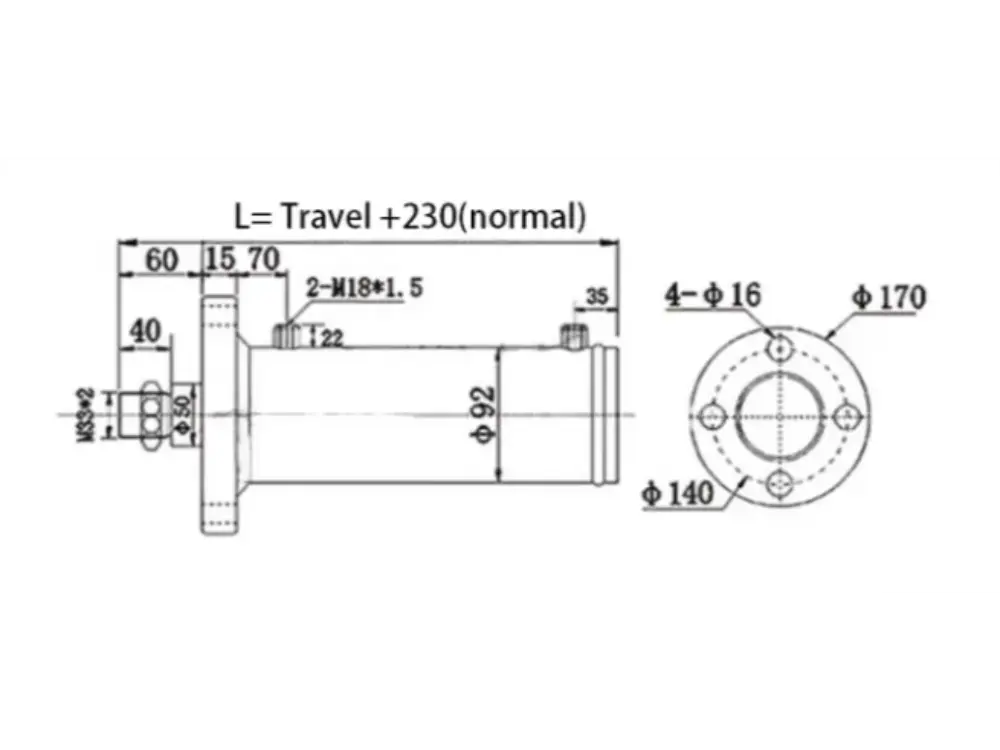

| Model | HSG-E-FA-80/50-200 |

| Rated Pressure | 16 MPa |

| Rated Speed | ≤50cm/S |

| Linear thrust | 8 T |

| Weight | 16 KG |

| Color type | Customization |

| Port Size | M18*1.5 |

| Mounting Type | Flange-mounted installation |

Installation and use instructions:

Correct installation:

Ensure the perpendicularity and levelness between the fixed flange of the hydraulic cylinder and the fixed point of the piston rod.

The hydraulic hose threads must be properly matched, with attention to the compatibility of the thread connection’s sealing type.

Additionally, effective measures should be taken to prevent dust or debris from entering the exhaust port.

Maintenance:

Before starting, check the connection and seal of the hydraulic cylinder to ensure there is no leakage.

During work, follow the instructions in the equipment operation manual to avoid overloading and over-speed operation, and ensure that the hydraulic cylinder operates under normal working pressure.

Instructions for use:

Before starting the machine, inspect all connections and seals on the hydraulic cylinder to ensure there are no leaks.

During operation, follow the equipment’s manual closely to avoid overloading or excessive speeds, and make sure the hydraulic cylinder operates within its specified pressure range. For initial use, fully extend and retract the cylinder, pausing for two seconds at each end to remove any air from the cylinde

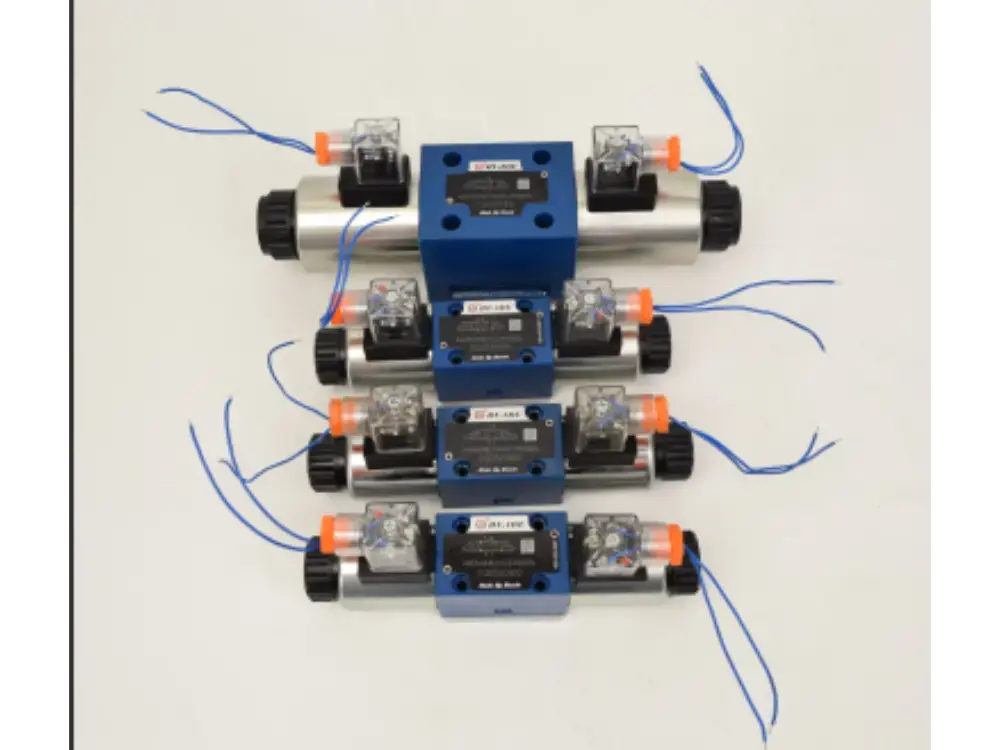

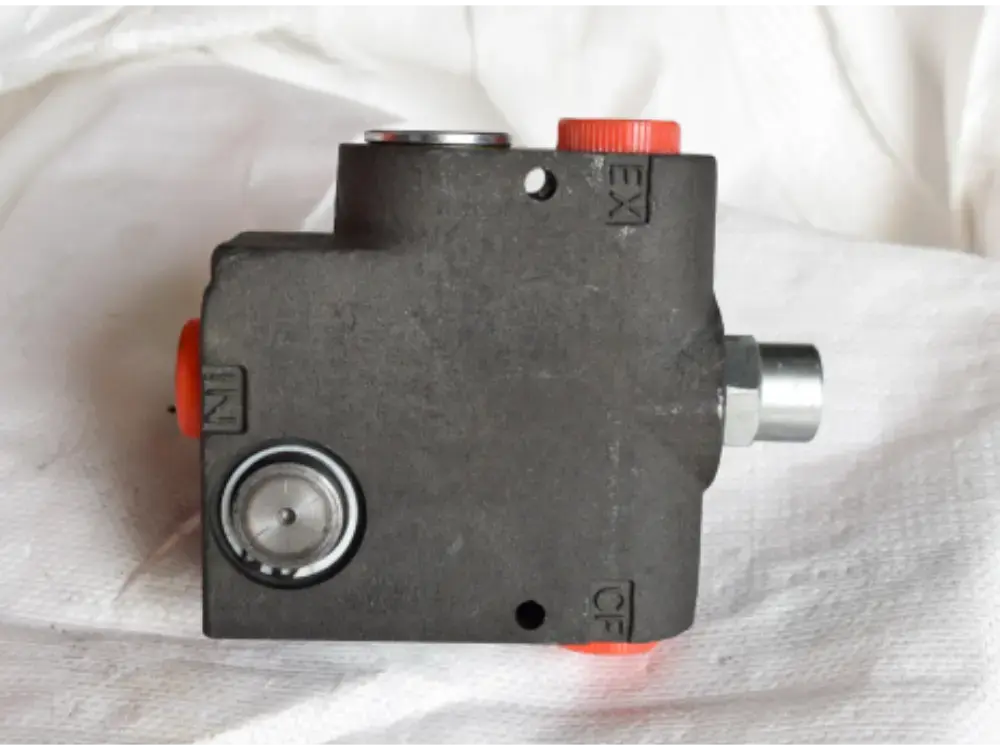

Required accessories and peripheral products:

Our components and peripheral products section includes a wide range of essential items such as power units, solenoid valves, hydraulic stations, hydraulic pumps, motors, and motor flow control valves. These high-quality products are designed to ensure optimal performance and reliability for your hydraulic systems, providing comprehensive solutions for various industrial applications.

After-sales service:

warranty period, return and exchange policy and other information

Warranty period

We provide a 12-month warranty for all hydraulic cylinder products. During this period, if the product has quality problems under normal use conditions, we will provide free repair or replacement services.

Return and Exchange Policy

Within 30 days after receiving the product, if the product is found to have manufacturing defects or transportation damage, you can apply for a return or exchange. Please keep the product and packaging intact and provide the corresponding proof of purchase.

Technical Support

We offer comprehensive technical support and assistance, including installation guidance, usage consultation, maintenance advice, and professional custom design services to meet your specific needs. If you have any questions, you can contact our technical team at any time by phone or email.

Spare Parts Supply

To ensure the long-term stable operation of the equipment, we provide original spare parts supply services, and customers can order replacement parts at any time according to their needs.