Heavy Duty Hydraulic Cylinder Manufacturer

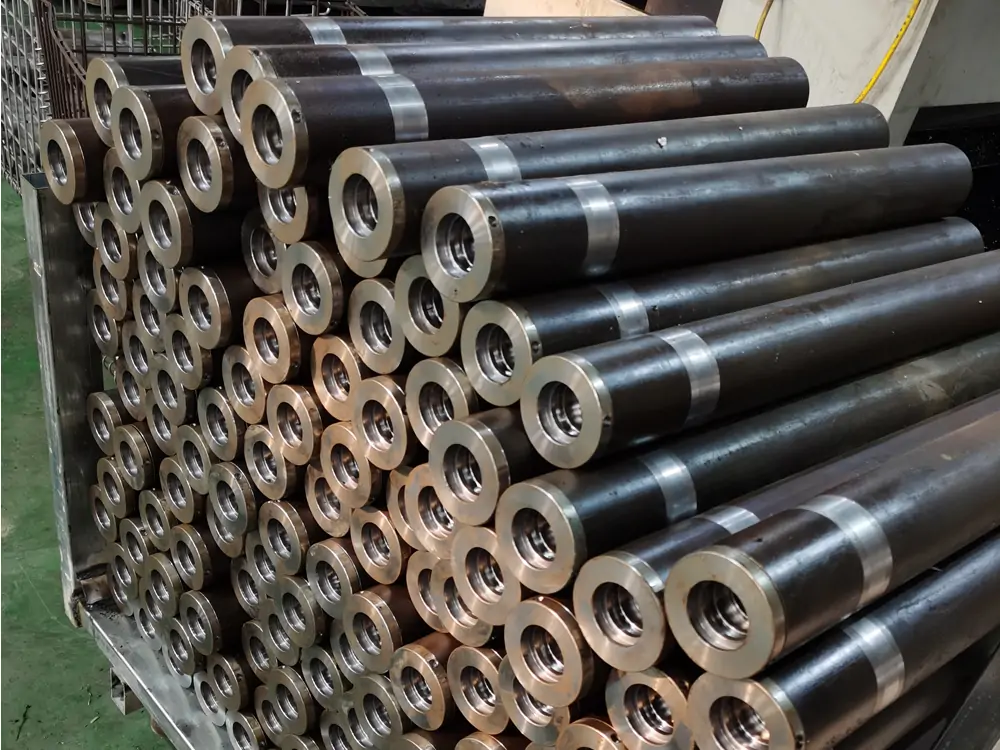

If you need a reliable and durable heavy-duty hydraulic cylinder, we are your best choice! As a leading Chinese hydraulic cylinder manufacturer, we are proud to provide high-quality hydraulic cylinder parts that withstand the most severe conditions.

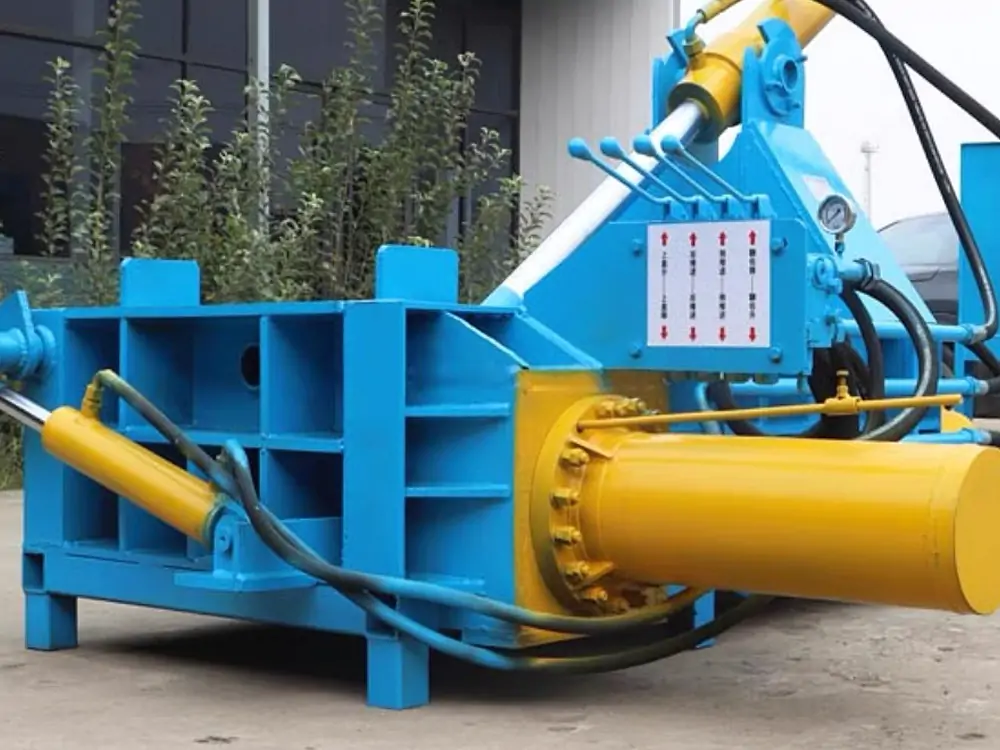

Our hydraulic cylinder components are well-designed to provide excellent performance and long-lasting durability. Whether it is construction or agriculture, our heavy-duty hydraulic cylinders are trusted by industries around the world for their reliability and efficiency.

With rich experience and pursuit of excellence, we are your trusted supplier of hydraulic cylinder parts. Whether you need a custom solution or a standard hydraulic cylinder, we have the strength to meet your needs.

Choose our heavy-duty hydraulic cylinders and enjoy unparalleled quality and performance. Contact us today for more information and discover why we are the first choice for hydraulic cylinder parts.