Hydraulic cylinders, known as the power hub of heavy machinery, are in demand today. They support lifting, pushing, and pulling heavy objects. But sometimes, operators face a severe issue of high-pressure buildup in those cylinders. Are you wondering how to relieve pressure on a hydraulic cylinder?

High-pressure results from an overflow of hydraulic fluid. This is a common issue and should be resolved immediately. Are you among those seeking a solution to this problem? Worry not! This article offers quick, reliable and easy tricks to tackle this issue. So, let’s get started without delay!

Why is it Important to Relieve Pressure on a Hydraulic Cylinder?

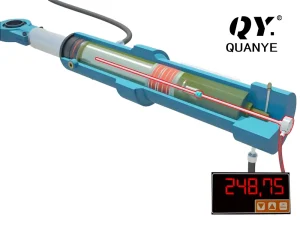

Hydraulic cylinders, with their unique setup, are an essential part of heavy machinery. They consist of a cylindrical body, a piston, a rod, and hydraulic fluid. The hydraulic fluid exerts pressure on the piston. When the piston moves forward, it automatically extends the attached rod. Then, this rod performs its duty of lifting, pulling, and pushing.

Sometimes, heavy loads or heating causes the hydraulic fluid to create high pressure in the cylinder. Such pressure can harm the cylinder body and affect its overall performance. Let’s discuss briefly why it is crucial to release that pressure.

1- Preventing Damage

As I said above, high pressure can damage the structure of hydraulic cylinders. Sometimes, this pressure is so extensive that it can rupture the cylinder’s body. Such a cylinder cannot be repaired or reused. Therefore, relieving the high pressure on time is crucial to prevent this damage.

2- Ensuring Safety

Personal safety is the most important thing when operating such risky machinery. If the high pressure ruptures the cylinder, boiling fluid will come out. This fluid can cause severe injuries to operators. Hence, it is vital to release the pressure.

3- Extending Equipment Lifespan

When the fluid flow is balanced, it ensures the efficiency of the hydraulic cylinders. No extended pressure means no risk of wear and tear of the cylinder’s parts. All components work correctly and have an enhanced lifespan. This not only saves you time but also money.

4- Maintaining Control and Precision

Once the fluid leaks due to higher pressure, it is almost impossible to handle it. The fluid gets contaminated, and you lose control of the whole system. Therefore, proper checking and relieving the high pressure ensure precision and control.

Methods to Relieve Pressure on a Hydraulic Cylinder

I am sure you have a basic idea about the importance of releasing pressure on a hydraulic cylinder. Right? Let’s move to diverse methods that keep your hydraulic system efficient. Remember, all these methods are double-checked and safe to implement.

Method 1: Manual Pressure Release Valve

Almost all hydraulic cylinders come with a pressure release valve. The manufacturers install this valve primarily to release high pressure. This valve is located near the hydraulic pump and is easy to access. The first thing you should do is to find that valve. It is an essential step because many other valves are also nearby.

When you notice high pressure on the hydraulic cylinder, turn on this valve. However, make sure the hydraulic powering system is switched off. Do not turn on the valve at once, as it can cause a hazard. Moreover, keep a pressure measuring device with you, such as a gauge. It will check the pressure level and prevent over-release.

Method 2: Lowering the Load

It’s obvious that high loads on the hydraulic cylinder increase fluid pressure to support the load. Simply put, the more load on the hydraulic cylinder, the more pressure is generated. Therefore, this method was introduced to handle this issue. This is a very straightforward procedure and doesn’t require special skills.

Simply decrease the load lifted by hydraulic cylinders. This process sends the fluid back into the reservoir, reducing overall pressure. However, do not lower the load at once. It can cause abrupt pressure changes, which can damage the machinery. Also, a gauge should be used to notice the pressure relief rate.

Method 3: Shutting Off the Pump

If you are new to hydraulic cylinders, this method is beneficial. As you know, a hydraulic pump is the heart of a whole cylinder. It is connected to a power supply that operates the pump. Turning on the pump generates pressure in the fluid that further pushes the piston.

When you shut off the hydraulic pump, the fluid supply stops. This means no further pressure is generated. Moreover, already-generated pressure starts relieving. This procedure provides immediate response in case of emergency.

Method 4: Bleeding the System

Often, the air is entered into the hydraulic pumps and generates air bubbles. Those bubbles increase the pressure of fluid and cause malfunctioning of the system. Therefore, it is crucial to release those bubbles. For this purpose, a specialized valve is present to bleed the system.

When you detect a high pressure, open that valve, and gradually, the bibble starts releasing. However, not only bubbles but also some fluids come out. So, when you have attained a safe pressure level, add some fluid again to the pump for efficient working.

Method 5: Using Bypass Lines

It is the most advanced pressure-relieving method of all. The modern design of hydraulic cylinders comes with a network of pipes known as bypass lines. Those pipes are directly connected to the main body of hydraulic cylinders. However, one end of these pipes is connected to the reservoir chamber.

When you notice high pressure, open the knob of these bypass lines. The extra fluid passes these lines and is transferred to the reservoir chamber. Surprisingly, these bypass lines have a sensor system. This sensor detects the over-pressure condition and immediately alerts the operators.

Safety Precautions When Relieving Pressure

The pressure-releasing methods of hydraulic cylinders are effortless. However, they also contain risk factors for the operators. To ensure safety, I’ll highlight essential steps before using these methods. Read them carefully!

- The fluid is released at high pressure. It is hot and can injure nearby operators. Therefore, Must wear protective clothes, goggles, and gloves.

- Before implementing those methods, ensure the power is switched off. This reduces the hazards of shocks.

- Do not stand by the fluid-releasing chamber. Always maintain a safe distance or hide yourself behind safety barriers.

- After shutting off the system, wait for some time. Do not implement those methods immediately.

- Before starting any method, ensure you have all the necessary tools. Do not use the wrong tools, as they can cause uncontrolled conditions.

- If you are new to the hydraulic system, always ask the experts for advice. Only try to apply a method with its knowledge.

- In the end, check the leakage properly. Ensure each valve is tightened and the fluid is not draining.

Frequently Asked Questions

How much pressure should a hydraulic cylinder have?

According to international standards, a hydraulic cylinder should have a maximum pressure of 700 bar(1000 psi). Pressure above this range can cause severe damage. The pressure should be released quickly for efficient working.

Can hydraulic pressure be adjusted?

Yes, hydraulic pressure can be adjusted. The hydraulic cylinder has several valves, such as manual valves, that control and adjust the pressure.

Can air get trapped in a hydraulic cylinder?

Yes, air can get trapped in the cylinder, leading to bubble formation. Those bubbles enhance the pressure of a fluid, so it is crucial to remove them by bleeding the system.

Conclusion

There are several ways to relieve pressure on a hydraulic cylinder. In this comprehensive guide, I have covered the easiest and most effective methods. For example, you can relieve fluid pressure with the help of specialized valves. Other methods include shutting off the power and bleeding the system. It is necessary to relieve that pressure immediately.

If not, it can cause serious results. For example, it can damage the cylinder’s body and affect its efficiency. However, all those methods should be performed by experts. Always prioritize your safety. Wear protective clothes, goggles, and gloves. Moreover, maintain proper distance and don’t touch the cylinder directly.