Bulldozers, lifters, and many other machines rely on the cylinder. The pressure created by hydraulic oil or air helps efficiently complete the heavy-duty task. Among those cylinders, single-acting ones are cost-effective and popular. But I still get the question: What is a single acting cylinder, and how does it work?

These cylinders have been in operation for many years. Some are very simple, others complex and equipped with futuristic features. However, their basic working principles remain the same. They all use fluid and apply pressure on the piston to do the job. In this guide, I will discuss every aspect of these single-acting cylinders. So, let’s get into the groove!

What is a Single Acting Hydraulic Cylinder?

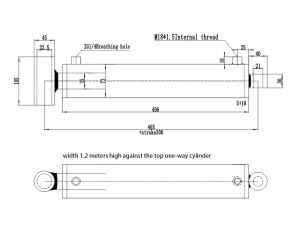

A single-acting cylinder is a one-way device that uses a piston. Fluid or air is used as the source of pressure. The cylinder consists of long cylindrical tubes that contain all the components.

Fluid press the pistons to complete our specific tasks such as bending and lifting. The piston returns through a particular spring.

These machines or cylinders are helpful in many ways. Let me give you some scenarios where these single-way cylinders come in handy:

- Apply pressure or load to press anything

- Lifting anything above the ground (lifter machines)

- Opening and closing the doors with proper forces

- Lifts of buildings that carry people from one floor to another.

- Braking and steering systems of cars and other vehicles

All these jobs would not have been possible without the role of these cylinders. What makes these single-acting cylinders popular is their simplicity. That’s why their usability in our daily routine is widespread. Have you ever noticed a door returning to its position when you open it?

Single-acting cylinders are the reason behind this action. These simple-looking machines are making our jobs effortless. Many of our works are impossible without their presence. What makes them stand out is their low pricing. It contributes to their aggressive usage in different vehicles and machinery.

Components of Single-Acting Hydraulic Cylinder

In the above section, I mentioned a brief overview of this cylinder. Want to learn about the workings of these single-acting cylinders? If so, I would like you to understand their components first. Why? Because those components work together to ensure the proper working of these cylinders.

You’ll only understand the workings of this cylinder when you understand its components. So, let’s have a look at their integral parts.

1- Main Body

This device or cylinder has a cylindrical tube-shaped body. It is a casing that carries all the other parts of these cylinders. Manufacturers make this body from strong materials, such as aluminum or iron, so it does not deteriorate. It is strong enough to withstand internal pressure. The fluid, piston, and other parts are present within this body.

2- Piston

The piston is a disc-shaped component present within the main body. It won’t be wrong to say that this controls the workings of these machines. This piston moves down and up by external force. But the question arises: How does this piston move in the cylindrical body? These cylinders use either fluid or air to apply force to the piston. As a result of pressure, the piston moves and performs specific tasks such as lifting and pressing.

3- Piston Rod

The piston rod is an extended, slender metal part that remains attached to the piston. It is the component that executes the specific task when the piston moves. Let me explain how this rod ensures the functionality of these machines. The hydraulic fluid or pressurized air applies force on the piston. As a result, this piston moves and generates motion.

This rod is specialized in transmitting that motion to the specific mechanism it is attached to. In simple words, it transmits the motion generated by the piston. For example, in lifters, this rod will execute the lifting mechanism. This rod achieves the press on the press machine. Piston movement helps this rod extend and do its job.

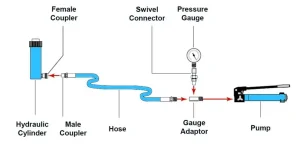

4- Pressure Port

In the above section, I mentioned that a piston is pushed through fluid or air. But don’t you wonder how this fluid or air enters the cylinder? That’s where this pressure port comes into play. This is a small inlet or fluid entry point. It offers a passage for fluid to enter into the cylinder and applies force on the piston to move. It is the crucial part that makes the working of these machines possible. Without fluids, these cylinders don’t work.

5- Springs

As you know, we are discussing the single-acting cylinder. Their single acting indicates they are one way. The fluid presses the piston to move towards it. But no fluid is available to bring it back to its original position. So, what makes it possible for a piston to return to its position? That’s where the spring system comes into the scene.

These single-acting cylinders have built-in springs. Once the piston completes its job, the spring pulls it back to its original position. Some high-powered cylinders use a pair of springs, as the piston is heavier. The spring system is the last component that ensures the piston returns and gets ready to press again.

How Does Single Acting Hydraulic Cylinder Work?

Have you grasped the essential components of a single-acting cylinder? If so, understanding how these devices work will become easy. The single-acting cylinder works its magic by relying on back-and-forth motion. There are three steps involved in making these cylinders work efficiently. Let’s discuss each of those.

1- Enter Fluid or Air

The working of a single-acting cylinder starts with the entry of fluid. As mentioned above, these cylinders use fluid or air to generate pressure on the piston. They consist of a small inlet where the fluid enters the cylinders. This entry of fluid is not random but very organized. The fluid enters the chamber of this cylinder. All this fluid remains on the one side of the cylinder above the piston.

2- Movement of Piston

The fluid or air inside the cylinder creates massive pressure on one side of the piston. Due to this force, the piston moves in the opposite direction. This piston movement is vital as it helps execute the specified task. The piston rod attached to the piston extends out due to the piston’s movement and completes the task.

For example, you have a small lifting machine with a single-acting cylinder. The piston rod attached to the piston moves, completing the lifting task. Different machines are available for other purposes, such as lifting, pressing, and bending. Thanks to the movement of the piston, this rod will do all those tasks.

3- Return to Original Position

After the task is completed, the piston returns to its position. But as I mentioned earlier, no fluid brings the piston back. As this cylinder is one-way, fluid only pushes the piston to move in one direction. So, how does the piston move in the opposite direction?

This is done through the spring that remains attached to a piston. So, where does the fluid go when the piston moves back to its initial position? This question is valid as fluid displaces the piston and presses downward. The fluid exits the chamber through the pressure port when the piston moves back.

It goes into the reservoir tank, which empties the chamber so that the piston can quickly return to its original position. The spring is the critical component in this process. Once the piston reaches its position, it can be pressed again. This process continues each time the machine performs any lifting or pressing task.

Advantages of Single-Acting Hydraulic Cylinder

1- Simplicity

The single-acting cylinders are very simple. They consist of fewer components that complement each other’s work. You don’t have to be too expert to operate them. You’ll need basic training to get the job done with these single-acting cylinders. Moreover, their wear and tear is also less common.

2- Energy Efficiency

These machines use no specific power source for their work. The hydraulic fluid or air is all that puts pressure on the piston. As a result, the piston moves down. The piston rod completes the required job. In the end, the spring returns the piston to its initial position. Did you notice any involvement of a part that required electrical energy or power? This makes these cylinders very efficient.

3- Compact Size & Reliability

These single-acting cylinders have a compact size. You can easily use them in any machinery. They don’t need a lot of space for their installation. That’s why they are prevalent in cars’ braking systems and doors. The operator of parts of these cylinders is very straightforward. There are significantly fewer chances of failure.

4- Less Initial Cost

Remember, there are different types of hydraulic cylinders available. Among all those types, the single-acting cylinders are the most inexpensive. Buying them won’t break your bank. Moreover, they do not require any regular maintenance. Why? Because they have straightforward functionality. Lesser components are involved in their work. All these things make this cylinder very affordable.

Frequently Asked Questions

1. What is the capacity of the single-acting cylinder?

The capacity of the single-acting cylinders varies depending on their size. On average, they have a capacity of around 10-200 tons. More giant cylinders can have more capacity, and vice versa.

2. How many ports does a single-acting cylinder have?

Single-acting cylinders have only one port on one side of the cylinder. Fluid or air enters and exits the cylinders through this port.

3. What are the limitations or drawbacks of the single single-acting cylinder?

These cylinders are limited in their capacity. They do the work by applying force from one side, which makes them less versatile. Moreover, the spring used in these cylinders is prone to wear and tear, which is a big issue. However, they are simple and less expensive, which adds value to money.

Conclusion

Single-acting cylinders are standard in different machineries. They are also commonly used for doors to car brakes. These cylinders are very simple to operate and install. They use simple working principles and utilize pistons and hydraulic oil to get the job done.

What I like about these cylinders is their cost-effectiveness. These single-acting cylinders are used extensively in many industries. In this guide, I explain everything related to them. Hopefully, it will help you buy and use them.