Custom Hydraulic Cylinder Manufacturer

As a Chinese hydraulic cylinder manufacturer and hydraulic cylinder parts supplier, we are committed to providing you with high-quality customized hydraulic cylinders and hydraulic cylinder components. No matter which part of the hydraulic cylinder you need, we can meet your needs.

With an experienced team and advanced production equipment, we can customize various hydraulic cylinders according to your requirements to ensure that their quality and performance reach the best level. Whether it is the design, manufacturing or after-sales service of hydraulic cylinders, our primary goal is customer satisfaction.

If you are looking for a reliable hydraulic cylinder manufacturer and parts supplier, please contact us and we will wholeheartedly provide you with professional solutions. Thank you for your attention!

Customized hydraulic cylinder parameters

| Customization Options | Customization Content |

| Specifications and dimensions | Stroke Length: up to 6000mm Bore Diameter Rod Diameter Piston diameter: up to 1000mm Total length: up to 9000mm |

| Material | Cylinder body and piston material (such as steel, aluminum, coating, etc.) Sealing material (such as fluororubber, polyurethane, etc.) |

| Working pressure | Up to 40MPA |

| Drive mode | Single-acting cylinder or double-acting cylinder Working mode (such as acceleration, deceleration, etc.) |

| Sealing system | Type and layout of sealing rings Wear resistance and pressure resistance |

| Installation and interface | Installation method (such as flange, suspension, etc.) Hydraulic interface type (such as thread, quick connector, etc.) |

| Functional requirements | Additional functions (such as buffer device, induction device, etc.) Special purposes (such as explosion-proof, high temperature resistance, etc.) |

| Performance parameters | Thrust and pull calculations Speed and response time |

| Tests and standards | Industry standards that comply with (such as ISO, DIN, etc.) Quality control and testing requirements |

| After-sales service | Warranty policy and maintenance recommendations |

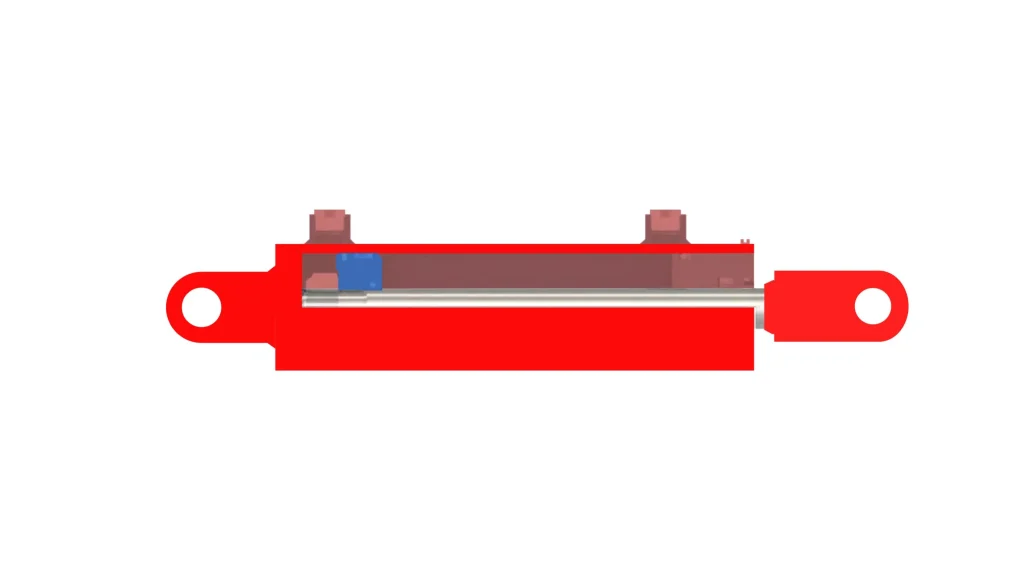

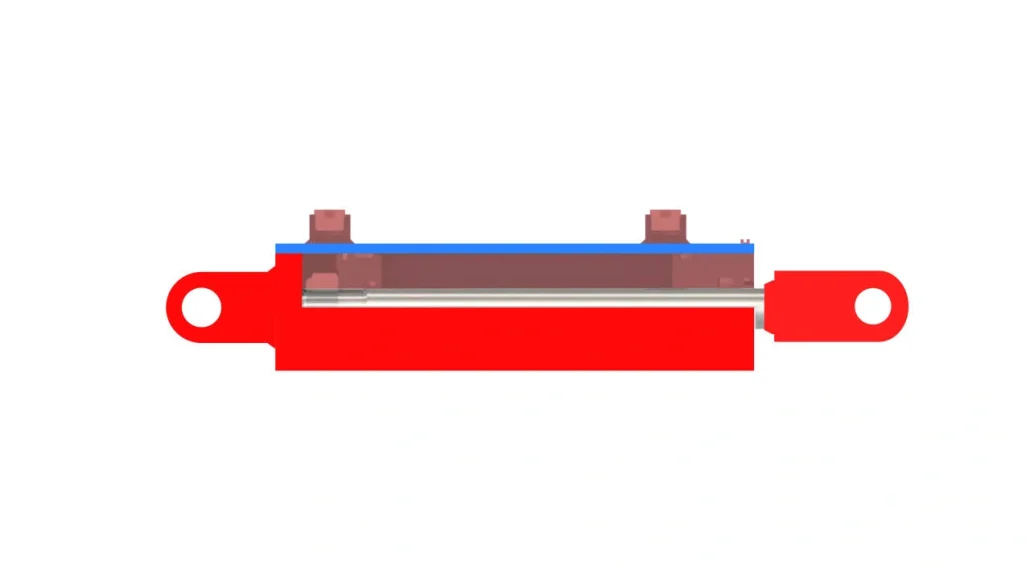

Custom hydraulic cylinder details display

Quanye hydraulic-cylinder offers custom design and manufacturing of hydraulic cylinders. We meet the needs of any application. Below are common hydraulic cylinder components, accessories, and functions. We also have a design department that customizes cylinders to meet all customers’ needs.

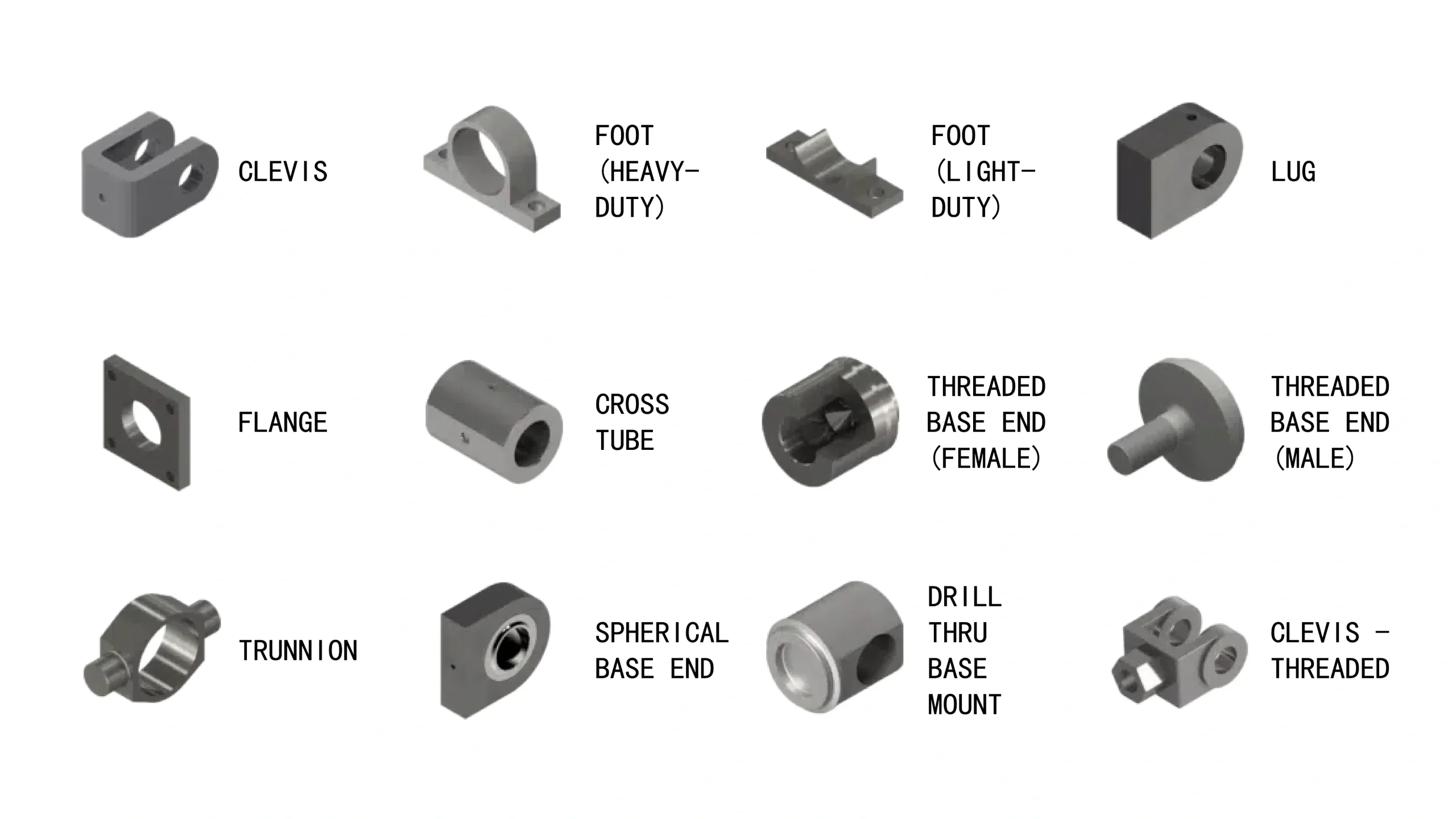

Common Base Mounts

Base Mount

The base mount is located at the other end of the cylinder head. It fixes the cylinder to the machine body and is a versatile alternative to welded bases. It makes repairs and maintenance easier.

- Welded to the end cover or integrated with the end cover

- Precision-machined pin holes and mounting widths to ensure the right machine mounting position

- Wear-resistant bushings or bearings are available to reduce wear and increase durability.

Internally Threaded Head Gland

Undergo rigorous quality testing to ensure full fluid manufacturing performance and extreme reliability. These hydraulic cylinder parts secure seals, wipers, and bearings. They ensure the equipment operates as specified.

- High-strength ductile iron.

- You can fully service the cylinder. Just unscrew the head gland with an adjustable wrench.

- Radial screws prevent the head from stripping during operation.

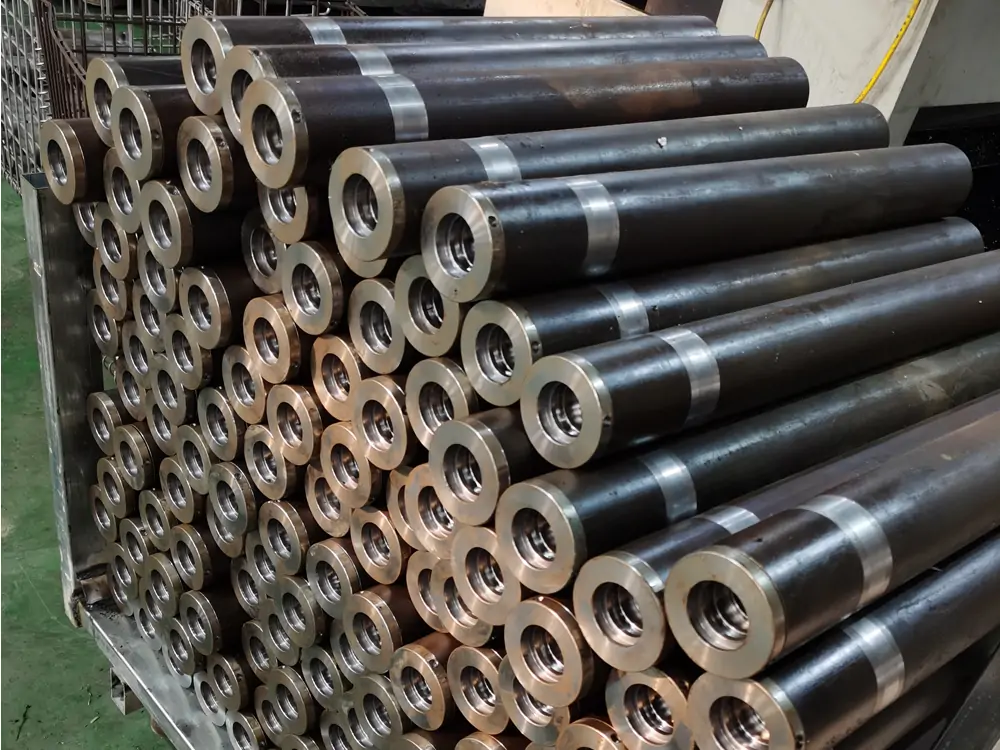

Pistons

The piston in the hydraulic cylinder barrel withstands the force of the hydraulic oil, allowing the cylinder to extend or retract. Pistons are used in single- and double-acting cylinders. They are usually machined with many grooves to keep seals.

- High-strength ductile iron

- Standard bidirectional piston seals and wear bearings.

- Secured with a nylon insert locknut

Rod

The hydraulic cylinder piston rod is on the piston. It passes through the cylinder head. The piston rod connects the cylinder to your equipment. Any required mounting accessories will connect to this component.

- Quenched and tempered and high-frequency hardened chrome-plated piston rod. The Mohs hardness of ordinary untempered chrome is about 5. After quenching and tempering, the hardness can reach 28. After high-frequency quenching, it can reach more than 50. Quenching is for surface hardness, not easy to break, not easy to bend. The surface quenching hardness is high and not easy to scratch and bump.

- Designed to withstand the maximum tensile and bending loads of the application

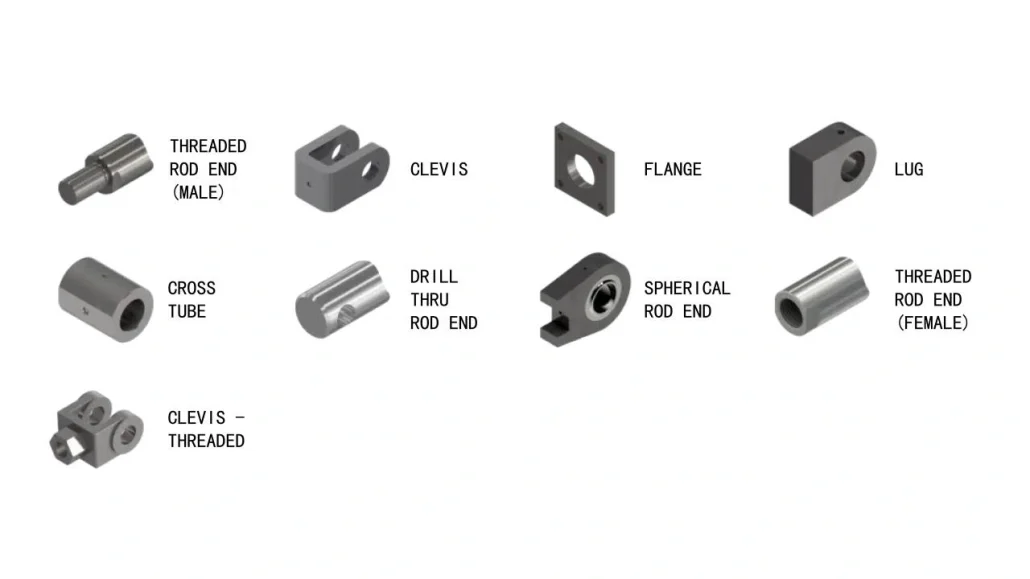

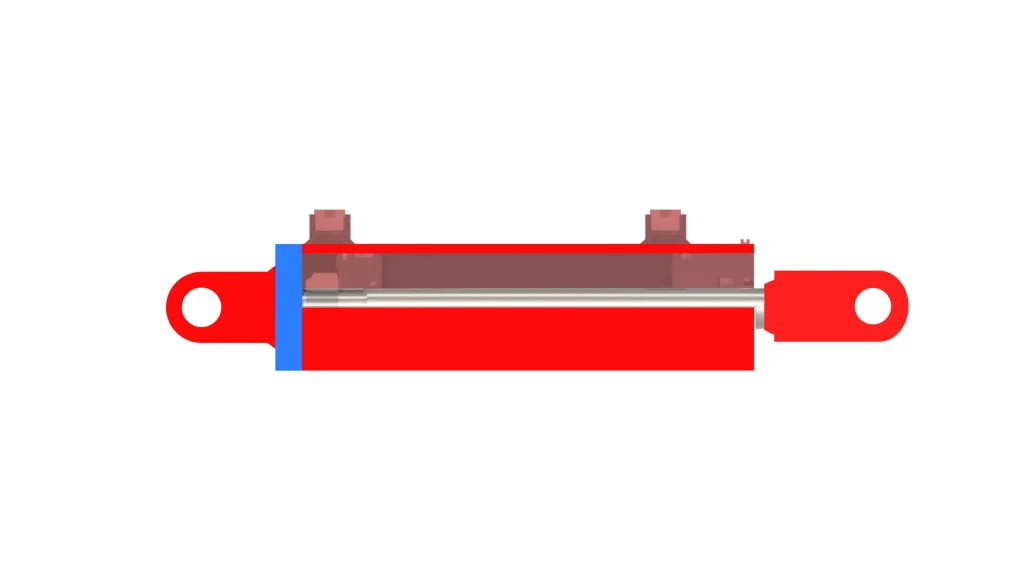

Common Rod Mounts

Rod Mount

Rod mounts are used to attach hydraulic cylinders to equipment and machinery. Rod mount cylinder assemblies align and protect cylinders from side loads. They attach to hydraulic cylinder rods. Available in a variety of sizes and configurations to meet your specifications.

- Typical welded robustness

- Threaded options available for easy maintenance or length adjustments

- Bushings or bearings available for increased durability

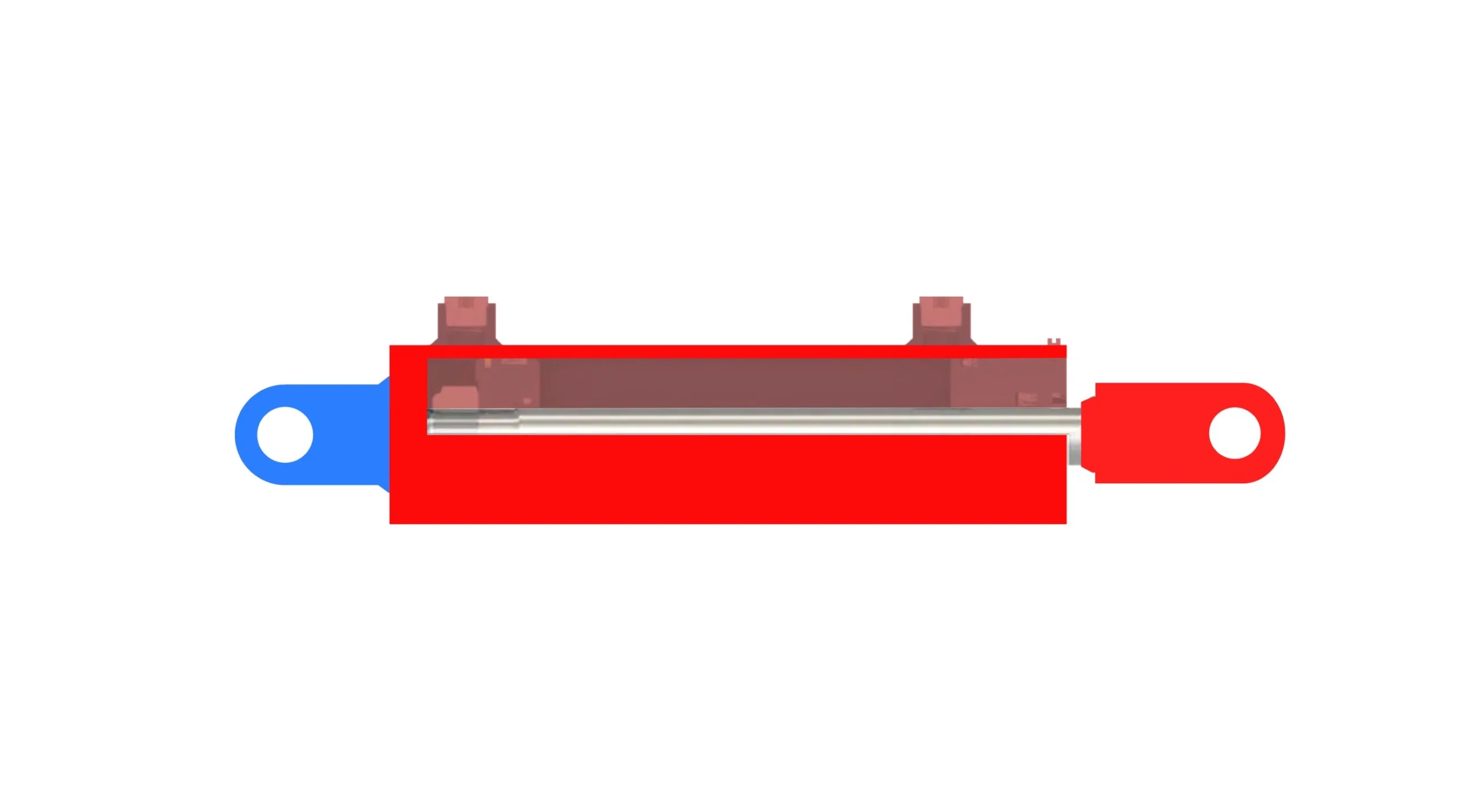

Tube/Barrel

The hydraulic cylinder barrel contains the piston and rod. This hydraulic cylinder component is closed by a cap on one end and a gland on the other. The barrel, also known as a tube, is built to withstand the harsh conditions and rigors of any application.

- Tough 45# steel

- Designed with a 1:2 burst safety factor based on material strength and maximum application pressure Standard.

Welded End Cap

Full Hydraulic’s welded end caps provide consistent and reliable welded joints. Made in China, our welded end caps are guaranteed to be of high quality by high-precision methods and a robot arm. They perform well and last in any hydraulic cylinder.

- J-groove weld preparation

- High-strength welding wire

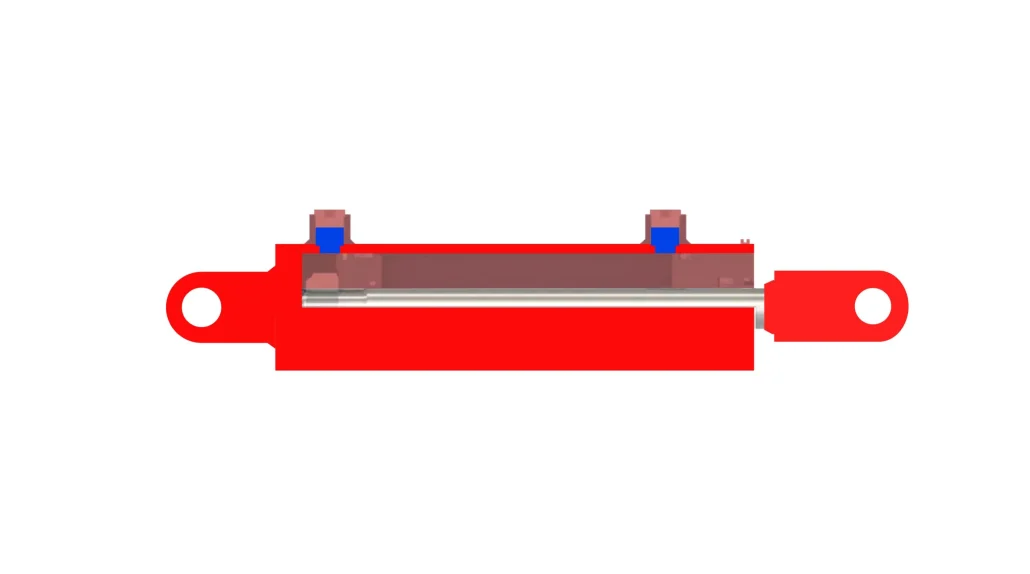

Welded Ports for Extend & Retract

We offer a variety of welded ports to meet the needs of any custom hydraulic cylinder. These critical components allow fluid to flow in and out of the cylinder and create motion. Ports should always be an important consideration in any custom hydraulic cylinder design.

- Freedom to specify size and type, regardless of bore size

- Ports can be located anywhere around the circumference of the pipe

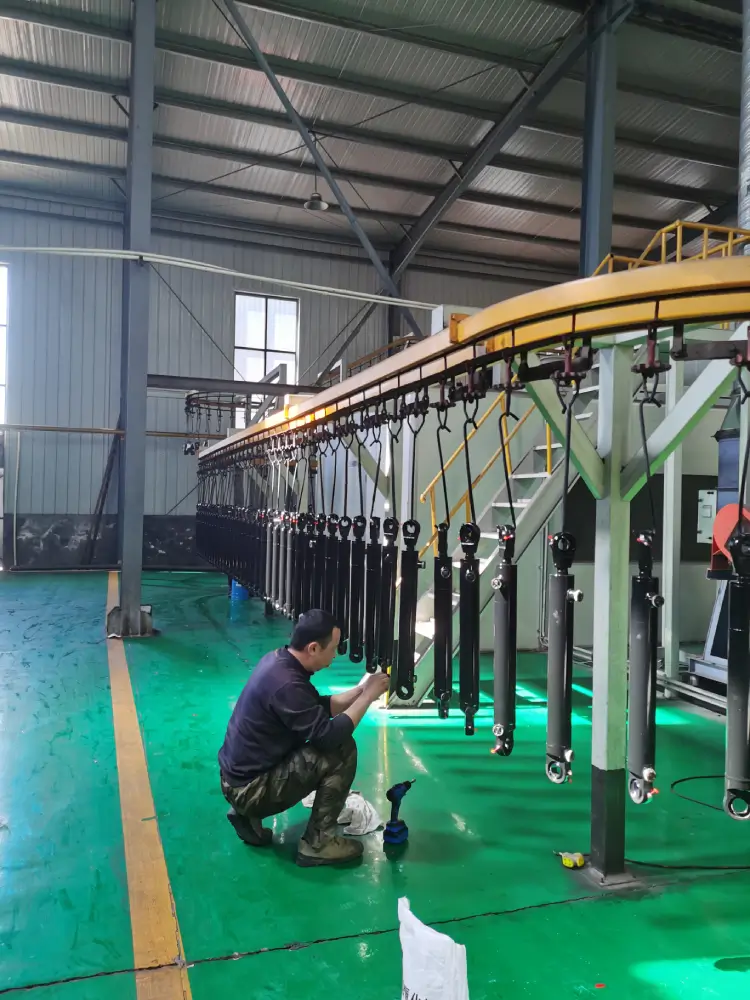

Quality Guarantee System

Program before Delivery

- Trial Operation Test

- Start-up Pressure Test

- Pressure-Tight Test

- Leak Test

- Full Stroke Test

- Buffer Test

- Testing the Effect of Limit

- Load Efficiency Test

- Reliability Test

Every piece of hydraulic cylinder are tested and will send out only after they are pasted the each test.

Choose the hydraulic cylinder according to your needs

Single-Acting Hydraulic Cylinders

Custom-made single-acting hydraulic provides power in only one direction. The hydraulic oil exerts pressure on the piston, and the rod moves forward. However, the piston rod needs external force to return to its original position.

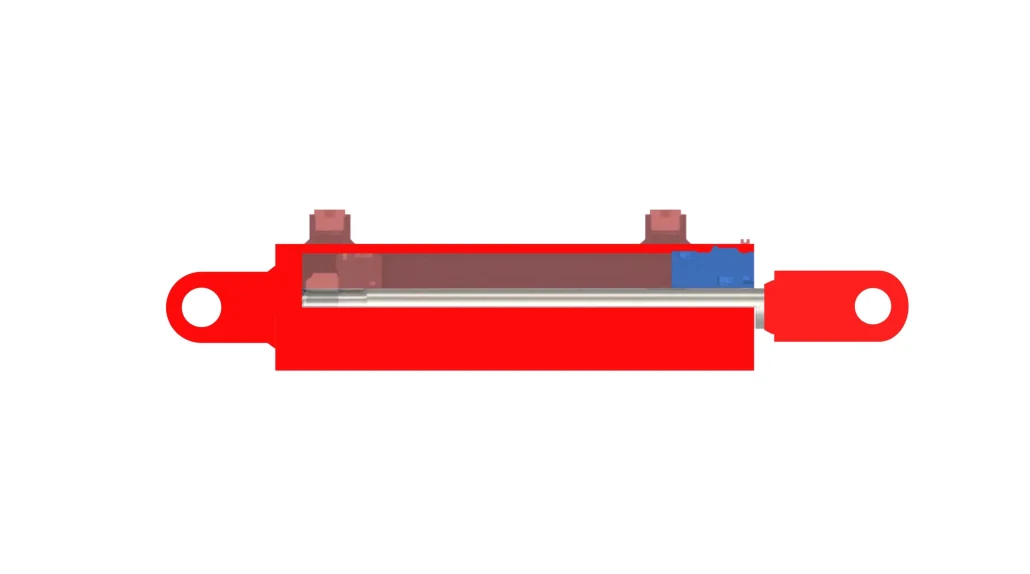

Double-Acting Hydraulic Cylinders

Double-acting hydraulic cylinder system is a powerful, advanced system. It provides twice the force and efficiency of a single-cylinder system. Double-acting hydraulic cylinders are commonly used in heavy-duty machinery and equipment

Heavy-Duty Hydraulic Cylinders

Our heavy-duty hydraulic cylinders are high-performing and reliable. They suit many industrial uses. Our heavy-duty hydraulic cylinders work in construction, mining, and agriculture. They ensure heavy machinery and equipment run well and last long. We are committed to providing high-quality products and excellent service.

Light Duty Hydraulic Cylinders

Welded Hydraulic Cylinders

Our welded hydraulic cylinder is a high-quality, reliable hydraulic system component. We use advanced welding and high-quality materials to make our products. This ensures excellent performance and durability.

Front Flange Mounted Hydraulic Cylinders

Our front flange mounted hydraulic cylinders are designed for easy installation and provide reliable and efficient performance for a variety of heavy-duty industrial applications. With their durable construction and precision engineering, these cylinders are the ideal choice for demanding hydraulic systems.

HSG Hydraulic Cylinder

The HSG series engineering hydraulic cylinder is a double-acting, single-piston rod hydraulic cylinder. You can match the installation method according to the actual application scenario. There are three types of hydraulic cylinders in engineering. They are based on connecting the cylinder head to the cylinder body. The types are external thread, internal key, and flange connections. They are primarily used in the hydraulics of engineering machinery and agricultural machinery.

MOB hydraulic cylinder

This series is an actuator. It converts linear motion into rotary motion in hydraulic systems. This product has two installation methods: flange and footrest. It has two connection forms: shaft and hole. The unique design of single and double racks suits various work conditions. The optional swing angle makes the product selection more convenient. This product is suitable for metallurgy, mining, and other industries

Hydraulic cylinder material

The main material we use to produce hydraulic cylinders is 45# steel. In addition to 45# steel, other materials can also be customized according to your needs. The material details are in the table below.

| Material:steel | Tensile Strength:MPA | Yield Strength:MPA | Elongation |

| 20# | 630 | 570 | 12 |

| 45# | 730 | 680 | 7 |

| 16mn | 640 | 570 | 13 |

| 25mn | 725 | 630 | 12.5 |

cold drawing process

Cylinder bore machining – rolling and calendering

- The workpiece surface is extruded and deformed by a high-hardness roller

- The surface metal is made to flow by the principle of plastic deformation

- A smooth and dense machining layer is formed on the workpiece surface

- Surface quality

- Higher surface finish can be obtained

- Surface hardness is increased by 15-30%

- A dense metal surface layer is formed

Piston rod material

45# steel is the material used for standard hydraulic cylinder piston rod. The production process of piston rod is heat treatment, tempering and quenching. The chrome plating process of piston rod surface is 1-5um, and the common one is 1um.

- High quality carbon steel grades: 35, 45, 50

- Alloy steel grade: 27SiMn, 30CrMo, 30CrMnSiA, 35CrMo, 38CrMoA1, 40Cr, 42CrMo

- Low alloy high strength steel grades:Q335B(C,D), Q335E

- Stainless steel grades: 20Cr13, 06Cr9Ni10, 304, 06Cr17Ni12-Mo2, 316, 12Cr18Ni9, 14Cr17Ni2

Heat treatment of piston rod

- Tempering treatment:

First, quench to improve material strength.

Then temper to eliminate internal stress and improve toughness.

Control the hardness between HRC28-32. - Surface hardening treatment:

Use induction quenching or high-frequency quenching.

The surface hardness can reach HRC52-58.

The depth of the hardened layer is generally 1.5-2.5mm.

Cylinder bottom earring material and forging process

The cylinder bottom and earrings are made of No. 20 steel (Q235) and are hot forged.

Hydraulic cylinder welding process

Oil cylinder welding adopts steam shielded welding. Automatic circumferential seam welding machine and mechanical arm automatic welding machine are used. The welding is uniform and consistent.

Types of hydraulic oil seals

The matching clearance is designed according to the diameter size, length, and pressure of our customers. The tolerance of product processing can meet the various industry standard requirements of customers, such as ISO1402. ISO9246 DIN24550. SAE J1395, etc.

- Copper gasket sealing

- Composite gasket sealing

- ED sealing ring sealing

- O-ring sealing

- Y-type sealing ring sealing

- V-type sealing ring sealing

- Glyd ring sealing

- Stef sealing

- Skeleton oil seal sealing